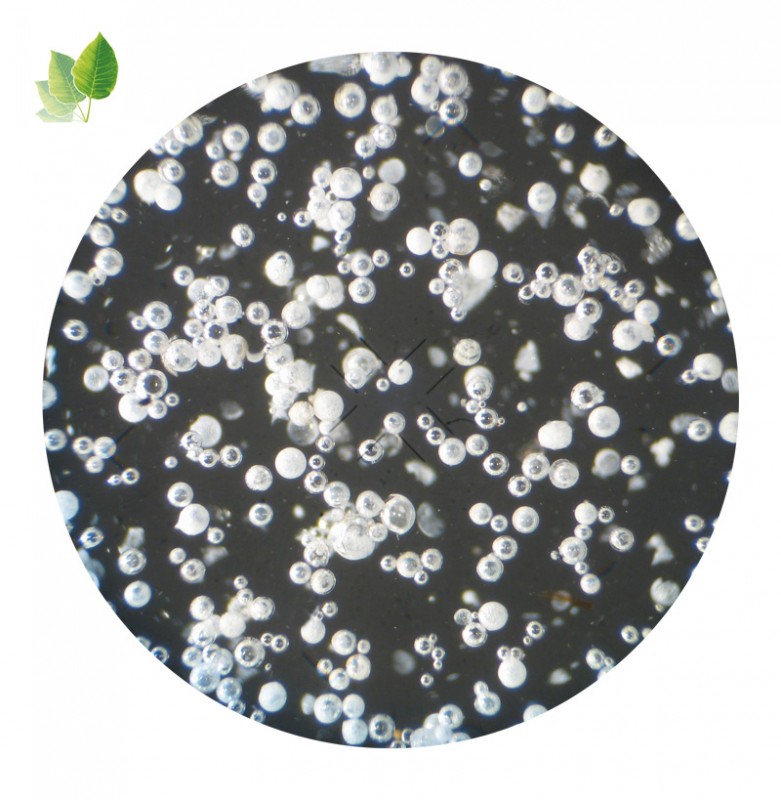

MICROSPHERES or CENOSPHERES are spherical alumina-silicate particles filled with nitrogen and carbon dioxide originating as a result of hard coal burning in power stations.

The granules (microspheres) transported together with slag to a sedimentation pond flow out over the water surface.

Microspheres are scooped from the water surface and they are transferred into a dripping chamber made of tarpaulin to lose excessive water. White microspheres occur naturally less frequent and are mainly used in applications, where high temperature, extreme heat and mechanical resistance are demanded. Also the brightness of particles are important to reflect heat as typical refractory material. Particle size of MICROSPHERES is from 5 to 500 / 300 / 160 micrometers (microns, μm).

ADVANTAGES

- High melting point 1300 – 1710 °C

- High compressive strength in composite solution and materials

- Non-flammable

- Improves thermal insulation

- Improves impact resistance

- Increases stiffness and nail/screw grip

- Reduce weight in composite solution and materials

- Rheological stable

- Chemically inert and non-absorbent

Alumina-silica spheres in our Microspheres AG have very low reactivity. The chemical composition makes our Microspheres AG extremely resistant to acids and alkalis. Microspheres AG are pH neutral and do not interfere or react chemically inside and outside the other products they are used in.

| Chemical name | MICROSPHERES, CENOSPHERES |

| CAS / EINECS | 93924-19-7 / 300-212-6 |

Photo

Specification

Application

- Refractories

- Oilwell Cements

- Geothermal Cements

- Tumbling Media

- Double Glazing Sealants

- Window Profile Cores

- Brake Linings

- Clutch Facings

DRYMORTAR & CONCRETE

Ceramic tile Adhesive

-

antisliding

-

increase layer thickness

-

improve workability

Renders, stuccos and plasters

-

improve workability

-

increase thickness

-

antisagging control

-

reduction of the shrinkage

-

reduction of the cracking risk

Cements boards and fiber cement boards

-

reduce weight

-

improve processability

Shotcreteand spray mortars

-

improvement of the product yield

-

reducton of the cracking risk

-

improve spraying

-

increase thickness

-

increase sagging control

WATERBORNE PAINTS & COATINGS

Texuralpaints, textures ands Thick layer paints

-

increase thickness

-

weight reduction

-

sagging control improvement

-

increase burnish resistance

Jointfillers for gypsum boards (drywall)

-

improve workability

-

antisagging control

-

reduction of weight

-

reduction of the shrinkage

-

reduction of the cracking risk

Elastomeric waterproofing coating

-

improve workability

-

imrpove abrasion resistance

-

improve durability

-

weight reduction of the coatingsystem

Specialflooring

-

improve workability

-

improve abrasion resistance

-

improve durability

-

weight reduction

ASPHALT – BITUMEN

Waterproofing emulsions

-

reduction of the sheet weight

-

flowing improvement

Waterproofing membranes

-

reduction of the sheet weight

-

flowing improvement at hightemperature

Sound dampening membranes

-

reduction of the sheet weight

-

flowing improvement at hightemperature

Masticand putties

-

improve workability

-

antisagging control

-

reduction of the shrinkage

-

reduction of the craking risk

RESINS & MOLDING (MOLDED ELEMENTS)

Unsaturated polyester resins

-

weight reduction

-

improve impact resistance

-

improve thermal shock resistance

Decorative elements based in epoxi resins

-

improve processability

-

weight reduction

-

increase durability

-

abrasion resistance

-

possibility of reduction in the resincontend

Polymersfor flooring & automotive parts

-

improve processability

-

weight reduction of the pieces

-

increase durability

-

abrasion resistance

-

improvement in the acousticproperties

Synthetic marble & artificial stones

-

improve processability

-

weight reduction of the pieces

-

increase durability

-

abrasion resistance

-

possibility of reduction in the resincontend

OILFIELD & REFRACTORIES

Lowdensity cements slurries

-

important improve of thelubricafication of the systems

-

reduction of weight

-

better flow characteristics (sphereshape)

-

reduced water absorption

-

improved insulation value

-

shrinkage and warping reduction

Refrac – Precast shapes (Firebricks, Burner blocks, etc…)

-

reduction of weight

-

improve durability

-

improve temperature resistance

-

improve thermal isolation

Refrac – Plastic masses, Fettling mix, Mortars

-

improve workability

-

reduction of weight

-

improve durability

-

improve temperature resistance

-

improve thermal isolation